History & Hickory

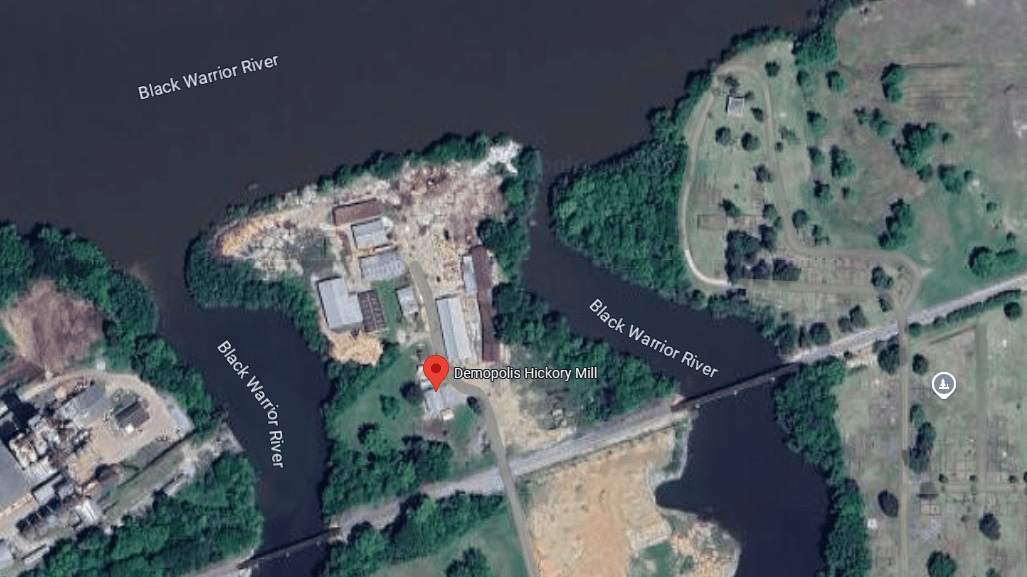

In Demopolis, a town in west-central Alabama’s Marengo County, located in the Black Belt region, lumber mills and the timber industry have long been a cornerstone of the local economy, shaping the area’s development over generations. One such mill has stood just off the banks where the Tombigbee and Black Warrior Rivers meet since the late 1800s.

In 1908, two businessmen from Manchester, England, relocated from the Memphis, Tennessee area — where they had been manufacturing snow skis from hickory and shipping them worldwide. Drawn by reports that the widest hickory trees grew along the Tombigbee River, they moved to Demopolis. There, they purchased a former pine shunt mill and established the Demopolis Hickory Mill.

Hickory stands apart from other lumber types due to its strength and versatility. It’s especially durable — ideal for tool handles, furniture, flooring, and sporting goods. Its shock-absorbing quality reduces the impact of blows, making it a top choice for striking tools. When burned, hickory imparts a distinctive sweet, smoky flavor to food, enhancing the experience of cooking over wood.

A New Owner for an Old Mill

Dan Lawrence grew up on a dairy farm, where he developed a talent for machinery while working with farm equipment. After high school, he became a sought-after mechanic, building a strong network of farmers who relied on his expertise.

One of his clients purchased a sawmill and asked Dan to run it, confident in his skills and trustworthiness. Dan accepted and successfully managed the operation for five years.

In 1988, Dan saw a new opportunity when the Demopolis Hickory Mill went up for sale. He purchased the business and, alongside his family, has been operating it ever since — producing hickory blanks, turnings, and striking tool handles.

Now 71, Dan works side-by-side with his son, Daniel, who turns 40 this year.

“He’s here with me, and that’s what I love about it,” Dan said. “It’s something that he’s going to take over. It’s just a lot of fun.”

Unprecedented Problems

Dan remains deeply involved in every part of the mill’s operation.

“I buy my own logs, I go out and price timber, I give people bids on it,” he explained. “Believe it or not, when they bring truckloads of logs in, I unload them and cut them into the links that I want into the the sawmill. When I’m not doing that, I’m running the saw, or watching somebody, or training somebody. If I could get my choice, I’d like to die out here at the mill.”

The COVID-19 pandemic in 2020 dealt a heavy blow to the business.

“We’ve made a decent living out of it until the pandemic hit,” Dan said. “Then the country shut down and they never did start back buying the handles like they were doing. So, that hurt us.”

Before the pandemic, over half of their sales were exports. That market all but disappeared, leaving a serious gap in revenue.

“When I bought this place, everything you cut every day was sold – you didn’t have to have sales,” Dan reflected. “Then, all of a sudden after the pandemic, somebody has to start selling this stuff and that’s just not my character. I don’t do a good job of selling things.”

Turning the Corner

When Angie Miller of the Marengo County Economic Development Authority learned of the mill’s financial struggles, she paid a visit to see how she could help. Dan expressed interest in both financial and technical assistance, so she connected him with Communities Unlimited (CU).

Through CU’s Entrepreneurship Team, Area Director Marnell Love worked with Dan to streamline operations, cut costs, and pursue new markets. CU’s Lending Team, led by Economic Development Loan Officer Chris Tillman, also helped secure a working capital loan.

Additionally, Marnell and Dan also corrected the company’s financial statements, negotiated interest-only loan payments, and implemented a turnaround plan. Within three months, the nearly 100-year-old family-owned sawmill gained new contracts, expanded into by-product sales, and even began talks with Mexico-based Truper Manufacturers. By year-end 2024, the business turned a $12,000 profit and achieved its first positive equity in years, preserving local jobs and positioning the company for growth.

The process with CU, Dan said, was smooth and supportive.

“It went just really easy,” he shared. “I gave them all the information they wanted and within a few days they did what they said they were going to do.”

A Promising Future

Recently, the business invested in equipment to convert unusable wood into hickory woodchips for cooking, and local restaurants have taken interest.

“They’re really excited that we can provide 100% hickory – most people will mix hickory and oak, and that’s the way they sell it,” Dan said. “They can’t do 100% pure hickory, but we can, and we can certify it if we need to. We’re really excited about branching out into this new thing.”

“My son’s got a boy who is nine years old, he’s got a mechanical mind like he and I got,” Dan said. “I feel like for sure he’ll be right out here with us when he graduates from high school. So, you know it’ll be something that stays in the family for years.”

Dan is deeply grateful for the help that brought them through the hard times.

“I just really thank God that somebody helped me get a jump start here.”

CU will continue to stand alongside the Demopolis Hickory Mill, helping one of the city’s oldest businesses remain a proud part of its future.